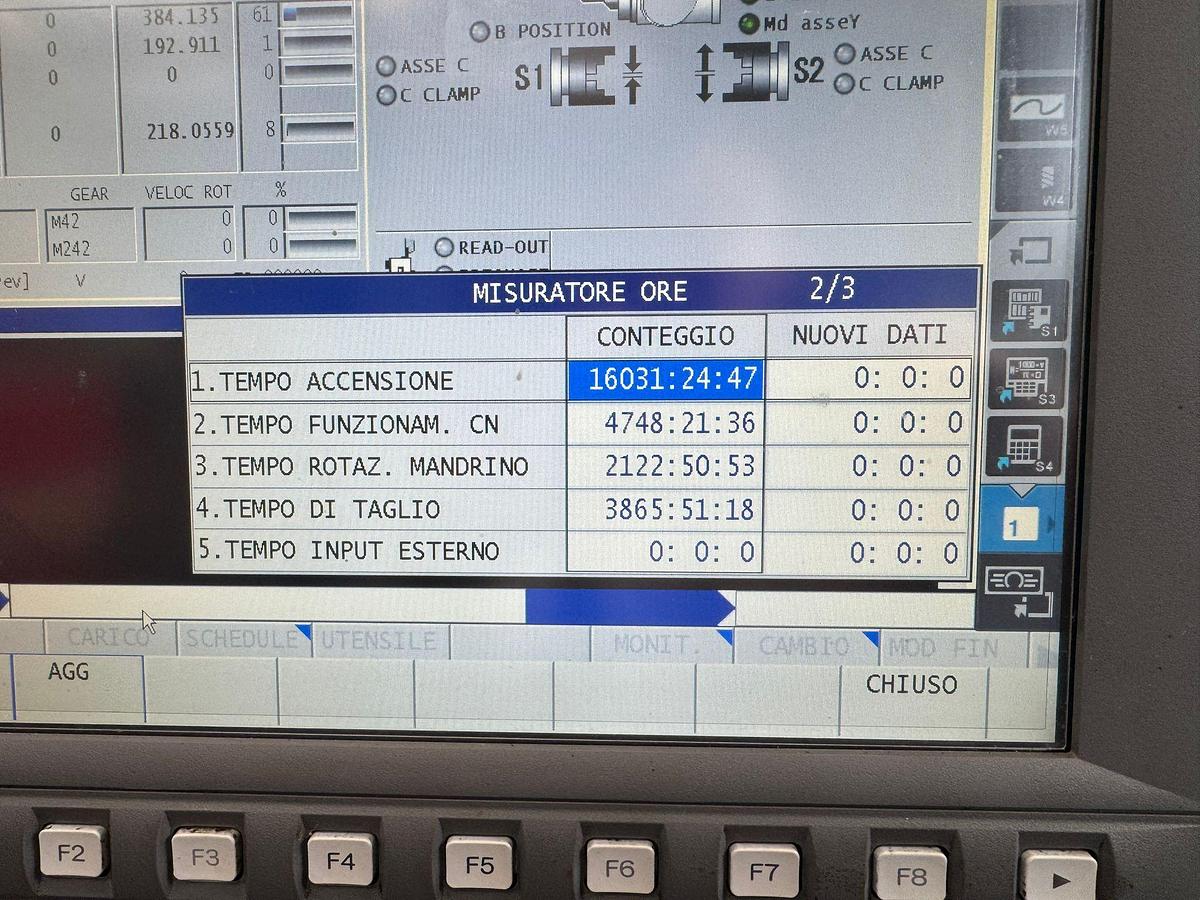

2016 OKUMA MULTUS B300 II

or

Call +39 030.2151206

Description

This 5-axis Cnc Turning center OKUMA MULTUS B300 II W was manufactured in 2016. It features an ASA 6 spindle offering 5,000 rpm and Ø 51 mm bar capacity, capable of handling a max turning diameter of 630 mm.

It includes a high-pressure coolant preparation of 70 bar, a continuous B-axis with HSK63, and a tool magazine ATC with 60 positions, optimizing both turning and milling capabilities.

- High-pressure coolant preparation: 70 bar

- External coolant pump: 0.8 kW, 6 bar, 20 L/min

- Electric spindle orientation

- Air blast for chuck cleaning

- Collision Avoidance System (CAS)

- Big Bore Spindle ASA 8": 22/15 kW, 3800 rpm

- High-precision C-axis positioning

- Continuous B-axis

- Tool Magazine ATC with 60 positions

- 0.1 Micron Resolution Software

- API Library 2 for OSP-P300S

- Standard Right Side Chip Conveyor

- 15 Bar Coolant Pump 20 L/min

- Filtration unit with 4 fabric filter bags (25 micron), pump 15 bar, 20 L/min

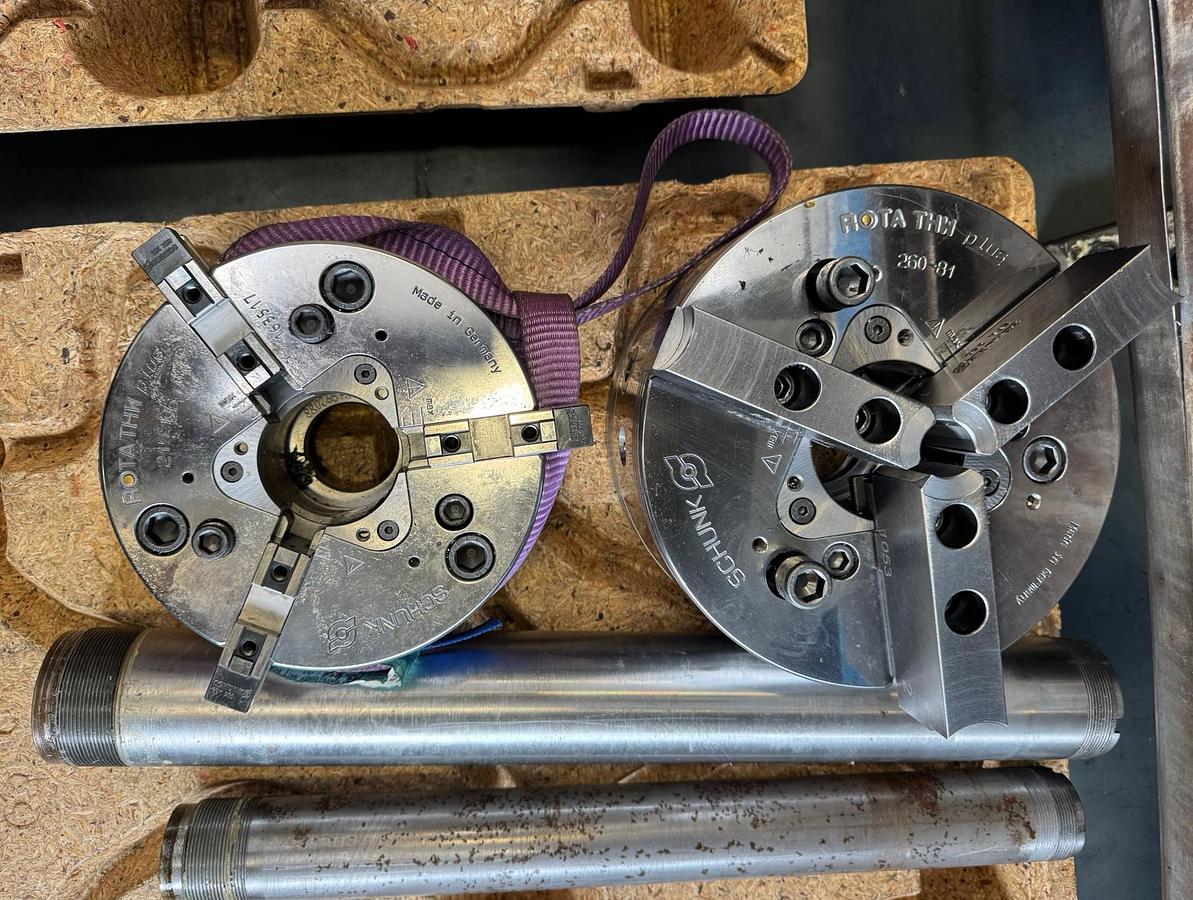

- SCHUNK ROTA THW+260-81R A8 chuck with KITAGAWA SS1770 cylinder for Big Bore main spindle

- SCHUNK ROTA THW+215-66 A6 chuck with KITAGAWA SS1452 cylinder for sub-spindle

- Y-Axis Machining Kit: Helical interpolation /Y-axis turning function with offset turning toolholders

- Coordinate conversion /Double pressure clamping system for main spindle chuck and sub-spindle chuck via M-codes (irreversible)

- 5-Axis Machining Kit: Super NURBS on 5 axes /Vector control /DNC-DT interface /Tool position control/ 3D coordinate transformation /Helical interpolation (includes inclined plane profile software)

Specifications

| Manufacturer | OKUMA |

| Model | MULTUS B300 II |

| Year | 2016 |

| Stock Number | 00153 |

| Type | CNC TURNING CENTER |

| Condition | Used |

| Status | Very good |

| Control type | OSP P300S |

| Max swing | Ø 630 mm |

| Max Machining | Ø 630 mm |

| Max bar capacity | Ø 51 mm |

| Max. spindle speed | 5.000 rpm |

| Spindle power | 15 Kw |

| Max. sub-spindle speed | 5.000 rpm |

| Sub-spindle power | 15 Kw |

| Y axis | 160 mm |

| B axis | continuos, index 0,001° |

| ATC Tool magazine | 60 positions |

| High-pressure coolant preparation | 70 bar |

| Equipment | Chip conveyor |